Two FMF Products won the title of outstanding products of machinery industry for the 40th anniversary of reform and opening up

Published on:

2018-12-19 13:25

On December 12th, good news heard from the China Machinery Industry Federation –FMF’s products: Automatic Air-Flow High-Pressure Squeeze Moulding Line and CNC Punching Line For Web and Flanges of U Beam with 5 Punching Units were both awarded the title of "40th anniversary of reform and opening up - outstanding products of machinery industry".

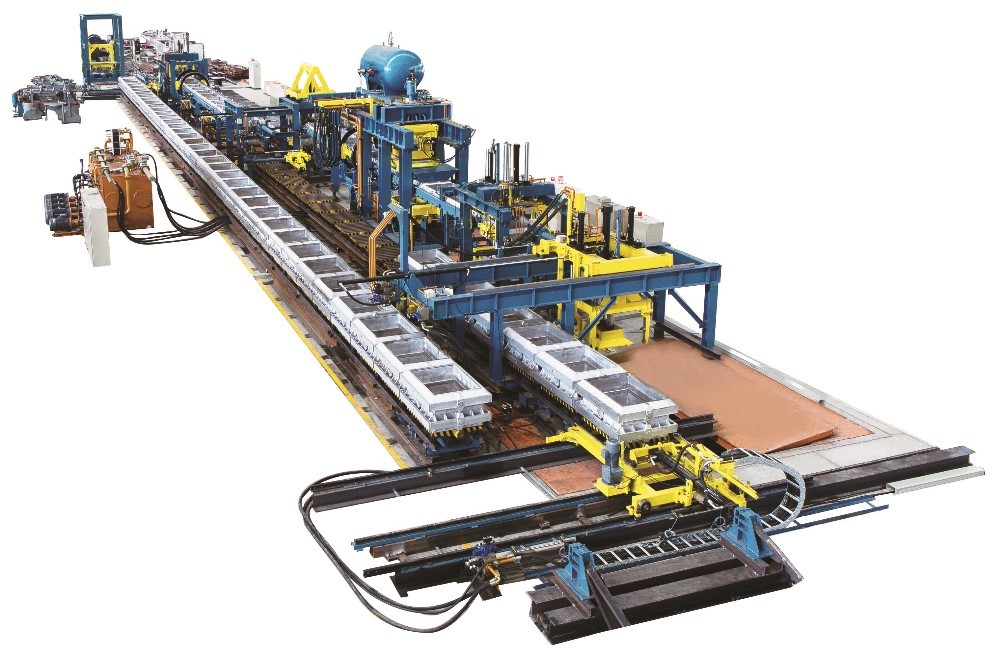

Automatic Air-Flow High-Pressure Squeeze Moulding Line

With compressed air and multi-ram high-pressure squeezing, the sand mold made with this process is high in compression strength and smooth on the surface. Clean, efficient, green and environmentally friendly make this the most advanced green sand molding process. Widely used in the casting production of automobiles, machine tools, railways, steel, electric power, textiles, chemicals, heavy equipment, energy power, pump and valve industries.

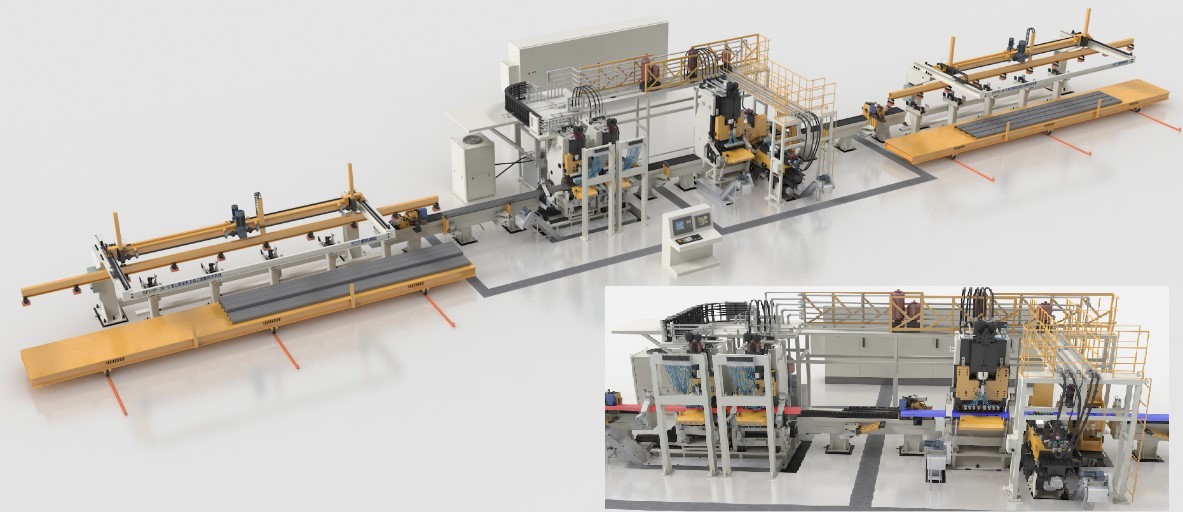

CNC Punching Line For Web and Flanges of U Beam with 5 Punching Units

With the functions of automatic loading and unloading, automatic feeding and positioning, automatic detection, automatic punching, etc., this line realizes fully automatic punching for the U beam of commercial vehicle frame. High precision, good flexibility, full automatic control, multi hosts combined machining (and simultaneous punching), U-beam shape error automatic measurement, and mold library for rapid mold change. This completely overturn the traditional drilling process. Suitable for automotive lightweight, green, high-strength sheet and tailored production, is surely a revolutionary product for commercial vehicle chassis making.

This line With high efficient production capacity (approximately 30,000 pieces per year per line), together with FMF’s uncoiling cut-to-length and slitting line, roll-forming line, automatic bidirectional bending line, robot cutting line, spot welding line, robot riveting line and painting, full-auto logistics transportation, full-auto processing, full MES management and control, realize the intelligent manufacturing of digital workshop for automobile frame. Since 2012, FMF’s domestic market share is 100%. Absolutely No. 1 in this field.

Previous

2019-12-09

2019-05-14